Vintage Tyres has got good form when it comes to bringing tyre moulds out of retirement and putting tyres that have been out of production for decades back on the racks.

We’ve made a number of brand-new moulds too, where the original had long since been scrapped, but there was clear demand for the tyre again.

When Do We Bring Tyre Moulds Out of Retirement?

The term ‘clear demand’ probably needs to be defined. It’s not a couple of sets for you and possibly that bloke down the pub. But if there’s a need for 500 tyres in the first couple of years of production, we will start the ball rolling with prices and lead times.

If 500 tyres sounds like loads, it’s around 49,500 fewer than you’d need to get a mainstream manufacturer interested.

How Do We Create Vintage Tyres From Scratch?

If you’ve ever wondered how the process of creating a tyre from scratch works, here’s an example from a few years back.

The team at Vintage Tures were approached by a group who raced historic motorcycle sidecar outfits. Their favourite tyre was out of production and, it was feared, might not be made again. Could we help? MD Ben Field takes up the story:

The sidecar men arrived for a meeting at Beaulieu. They singled me out immediately as a potential recruit for the ‘chair’ (the sidecar itself). There’s an ideal size/shape/weight, apparently, and I was it. As icebreakers go it was a good one, but these guys seemed serious. I quickly steered the conversation back to tyres – take a look at a historic sidecar race, and you will understand why.

The sidecar race series was well-established and had great support. Supply of the race tyre everyone used had suddenly dried up though, and without it the series would follow suit. There was no way we could get the mould from the manufacturer, so a new mould had to be budgeted in from the start.

Creating a New Tyre Mould

Mould costs vary. The larger the size and the more intricate the pattern the more expensive they get. We never charge outright for the mould. Some of its cost is factored into the price of the product of course. But if you want to talk about new sizes don’t fear a big upfront fee, there isn’t one.

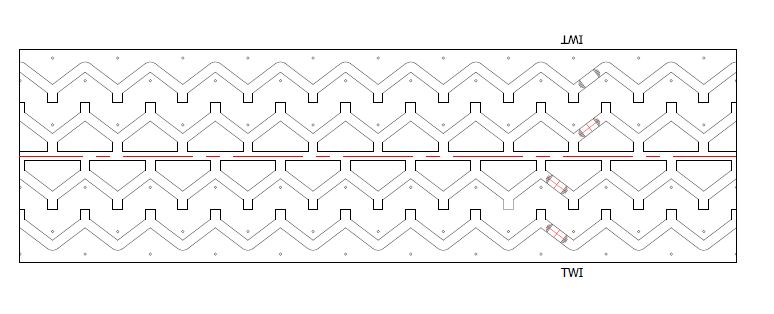

With the sidecar tyre we decided to work with Avon whose excellent motorsport department produced drawings of both tread pattern and sidewall design for approval by the racers. The compound, the recipe for the tread rubber itself, was also discussed in depth. The sidecar racers wanted a compound soft enough to grip in all conditions but hard enough to last a few races.

The mould took three months to make and the first samples were ready to test a month later. Testing takes place on a ‘rig’ which simulates extended use at a variety of loads and speeds.

The sidecar racers had their new tyre in time for pre-season testing on the track. From start to finish the process took just over a year.

Some tyres are quicker to develop, some a lot slower. But after an initial conversation we can normally provide a pretty accurate time frame for a new product.

Please get in touch or email Ben at [email protected] to discuss your project.